Ideal for lowering energy consumption in the pneumatic parallel suction conveying system

This valve is employed as a substitute of non-self-adjusting valves that are usually placed between cyclones and fan in pneumatic conveying systems that work through suction.

When used in place of those fixed-valves, self-adjusting valves allow to obtain constant speeds.

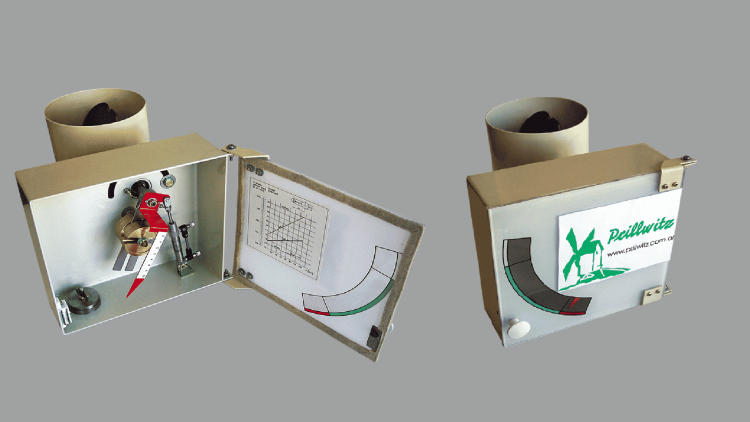

Self-adjusting valves work on the basis of the forces that are generated by interposing an airfoil-shaped piece to an air flow (See the chart below). By means of a counterbalance system, the air speed can be regulated in spite of changing amounts of product that circulate through this or other ducts.

Main advantages with respect to fixed valves:

– It saves energy, because products circulate through each duct at the proper speed thereby preventing over-dimensioning.

– Ensures quality in those products that deteriorate when conveyed at excessive speeds.

– Quite useful in thermo-pneumatic conveying where speed must be as low as possible.

Operating principle

S = drag force

M = resulting rotation

In a parallel suction pneumatic conveying system, if the load in kg/h of the conveying line decreases, its flow rate tends to increase. By having this valve, this causes the lift force S to increase, closing the valve, and thus balancing the flow rate again.