We have been supplying compressors for more than 60 years, when we started representing Aerzen of Germany.

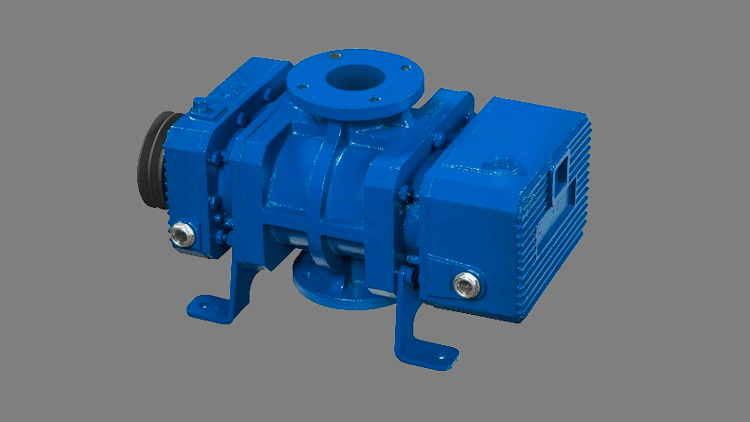

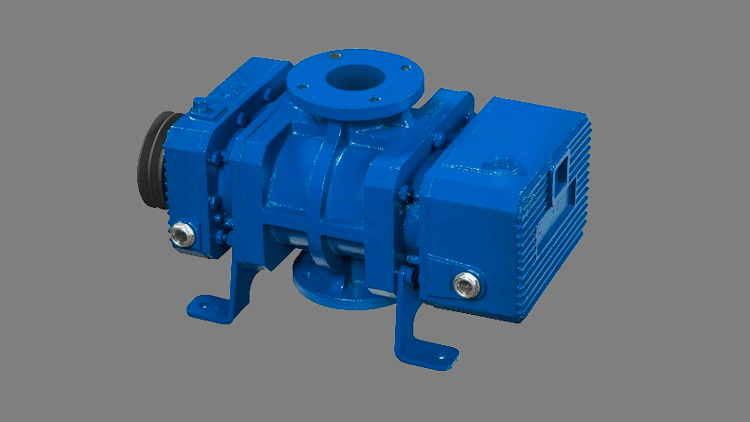

The 3-lobe rotor blowers of the ASR3 series have been researched and developed on the basis of the 2-lobe ASR2 series. The most important feature of this blower is the possibility to achieve high rotational speeds (up to 4000 RPM), which gives it a very high flow capacity

With the advancement of technology and developments from practical applications, we have achieved the ASR3 series blowers with higher performance, higher pressure, lower weight and less noise than the previous series. Inlet sizes range from 2.5″ to 12″ and pressure can reach 1 Kgf/cm2.

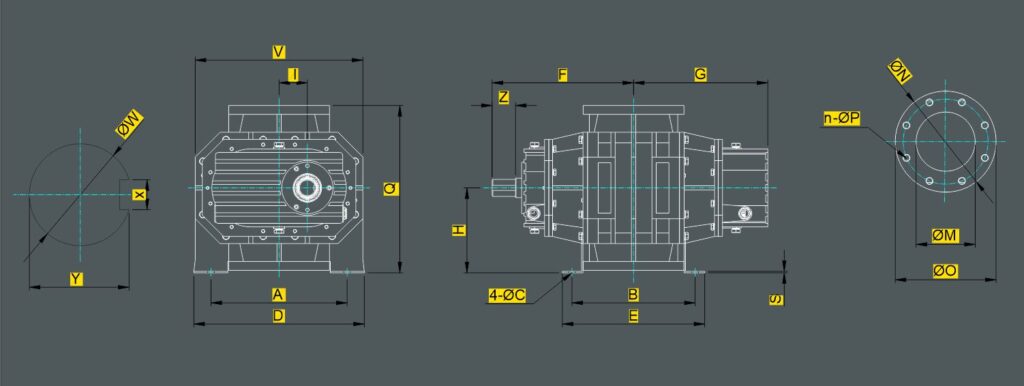

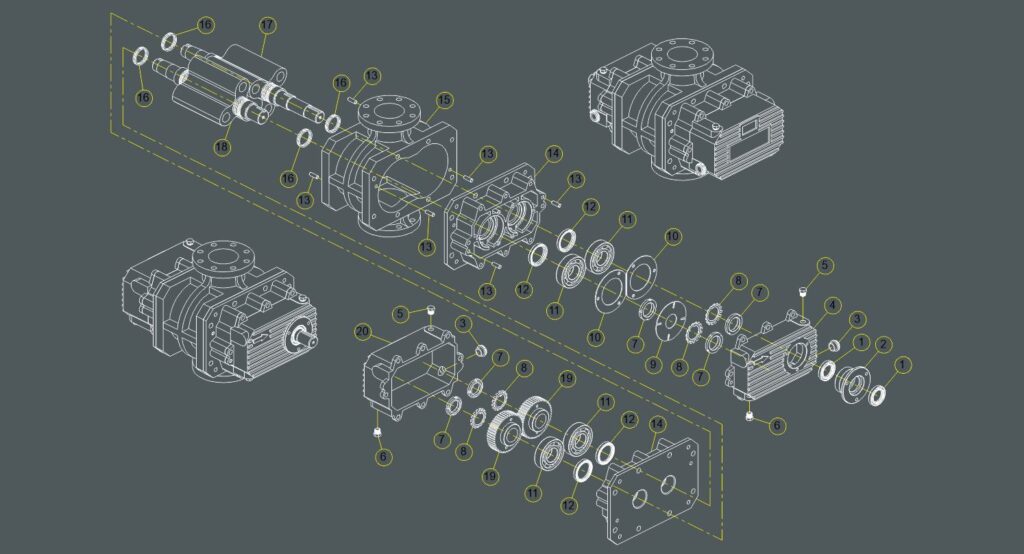

Design details of our rotary piston blowers

- High efficiency: Its linear structure reduces the sectional area of rotors to improve the blower capacity.

- Low vibration: High degree of balance accuracy (G2.5) can control the vibration of X, Y, Z coordinates.

- Low pressure loss: 180 degree vertical design between inlet and outlet reduces pressure loss.

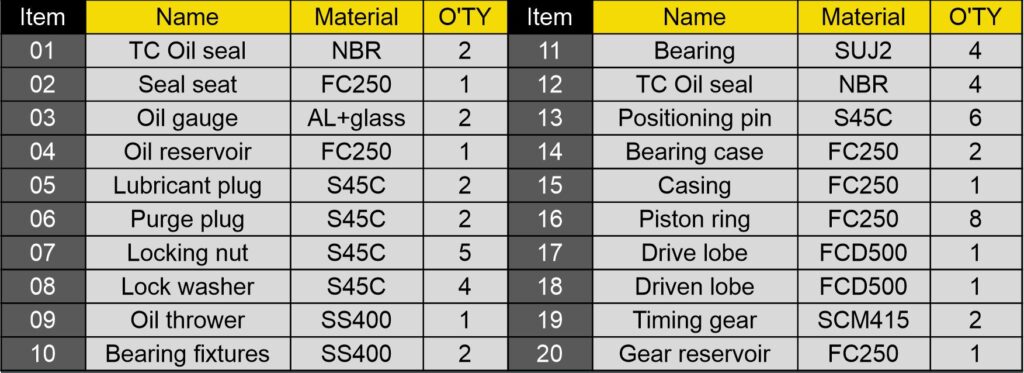

- High vacuum: The vacuum of single ASR3 blower can be up to -500 mmHg, and that of two-stage ASR3 blowers can be up to -650 mmHg.

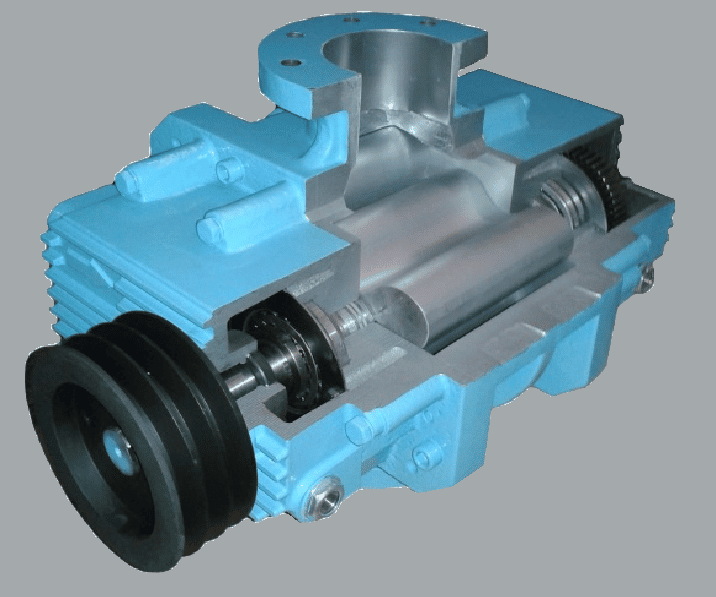

Roots type rotary piston blower operating principle

The ASR blower is a rotary parallel piston blower. The air flow is proportional to the speed of rotation of these lobes. At each rotation, each of the two lobes completes three times the air intake and discharge. In the case of the old 2-lobe blowers, this was done only twice. Thus, with the new 3-lobe blowers, we achieve the following improvements over the 2-lobe blowers:

- Smoother air flow

- Less pressure loss

- Increased durability

- Less noise and vibration

Each of the 2 parallel shafts has three lobes, and the lobes maintain a small clearance with each other and with the housing inside. At each complete rotation, a certain volume of air will be sucked in at the inlet and transferred to the outlet of the blower. The two shafts rotate synchronously by means of the drive gears. As there is no contact between the lobes, it is possible to rotate them at high speed, without the need for lubrication inside.

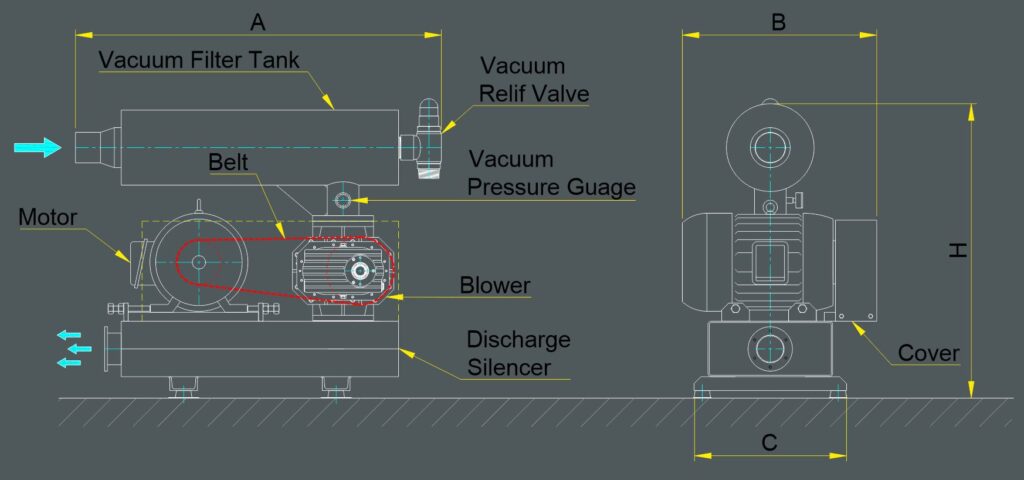

How to reduce the noise of a Roots type rotary piston blower?

To reduce the noise or sound intensity of a blower of this type, we can work on 3 aspects:

Lowering the speed or RPM at which the blower rotates: In cases where the RPM is high and noise can be a problem because of the place where the blower will be placed, it is recommended to choose a larger blower. In this way, the same flow rate will be achieved at lower RPM and with less noise.

Lower the working pressure of the blower: High pressures increase the noise or sound intensity (Db or decibels). In some cases, such as with a pneumatic conveying system, it is possible to lower the working pressure by increasing the diameter of the conveying pipe.

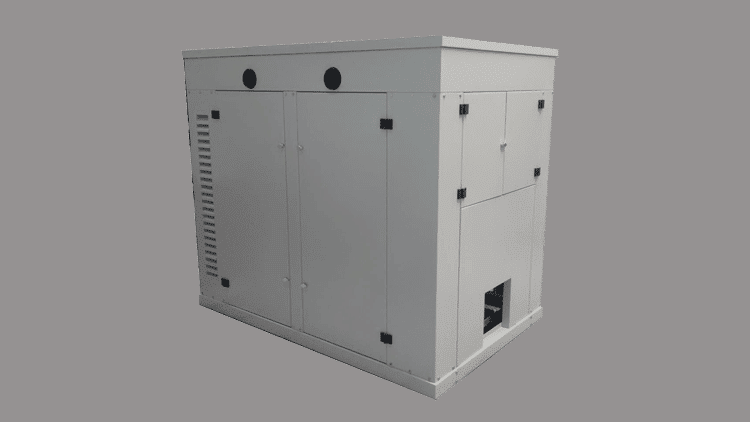

Fitting a soundproofing booth: When the sound intensity of a blower needs to be significantly reduced, our soundproofing booths can be fitted. They have easily removable covers for access to the blower. Blower control elements, such as pressure gauges, vacuum gauges, dirty filter detectors, etc., can also be moved to the outside of the booth for easy control.

Most common applications of our blowers

- Pneumatic pressure or suction conveying

- Aeration in drinking water treatment plants

- Aeration in industrial and sewage treatment plants

- Controlled atmosphere aeration

- Extraction of residues from petrochemical plants

- Numerous other special applications

Technical information

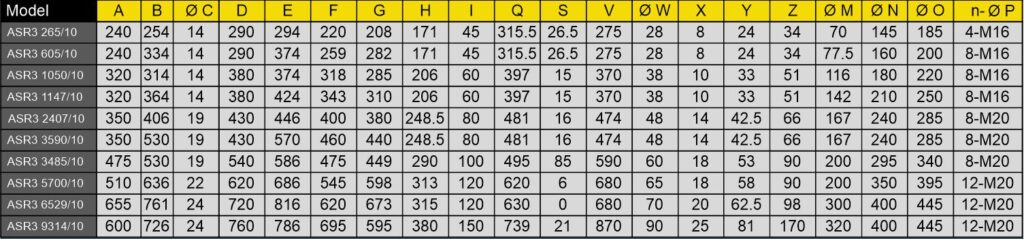

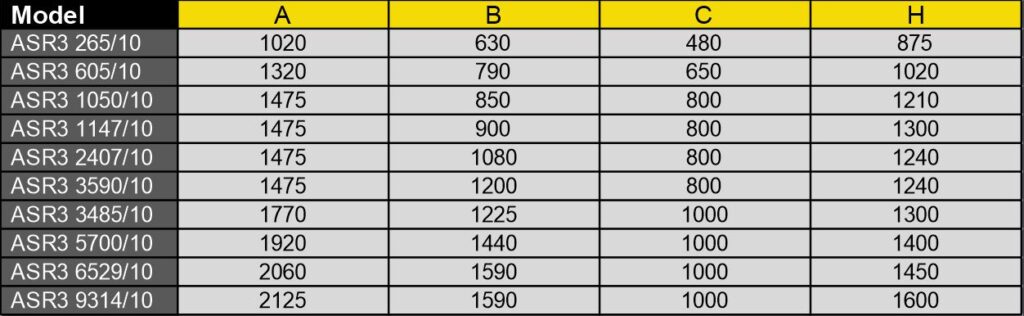

Main body dimensions

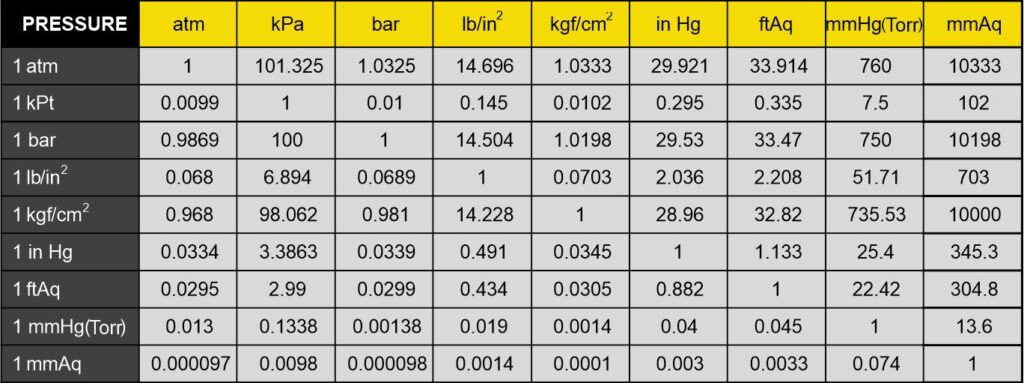

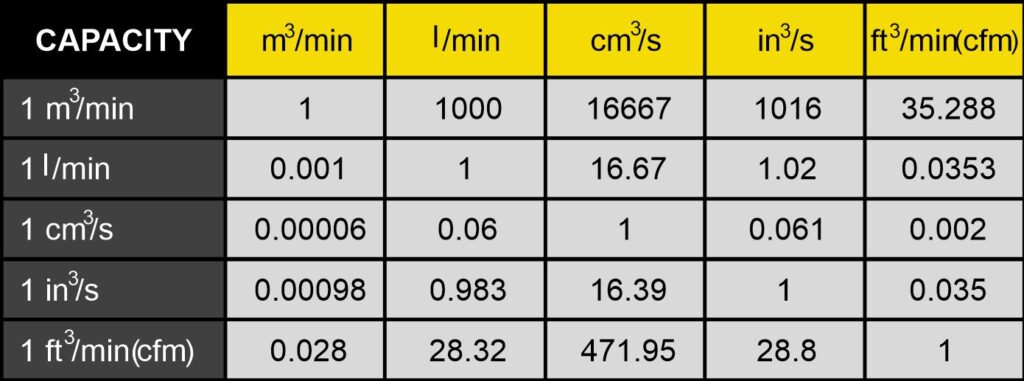

Conversion table

ARS3 Parts List

General suction dimensions

Overall Snap Dimensions

More information in the following links