Air channel classifier-separator of light particles from heavier ones, within a flow of material that slides through the product to be treated.

The tararas are part of the material classification and screening components. In this case, they separate materials by taking advantage of an air flow that passes through the product as it circulates through them.

Principle of operation of the Tararas or Air Channels:

In general, any separator or classifier takes advantage of the difference in any of the possible physical properties of the product to be treated, to make the separation. In the case of tararas in general and the Cylindrical Tarara TC in particular, the following characteristics of the product are used, which produce a different behavior when pushed by an air current: Difference in specific weight: It is clear that if we subject 2 particles of the same geometry to an ascending air current, it is possible to achieve that the light particle is carried by the air and the heavy one continues on its way. Difference in size: If we subject 2 particles of the same specific weight, but of different sizes, to an air current, the smaller one (because it has a greater surface area in relation to its weight) will have much more chances of floating and being carried with the air. air. Shape difference: Occurs in the case of 2 particles with shapes that make them more or less aerodynamic. For example, the case of a grain with respect to a shell or flat sheet.

|

How do the TC air purifiers achieve separation or classification?

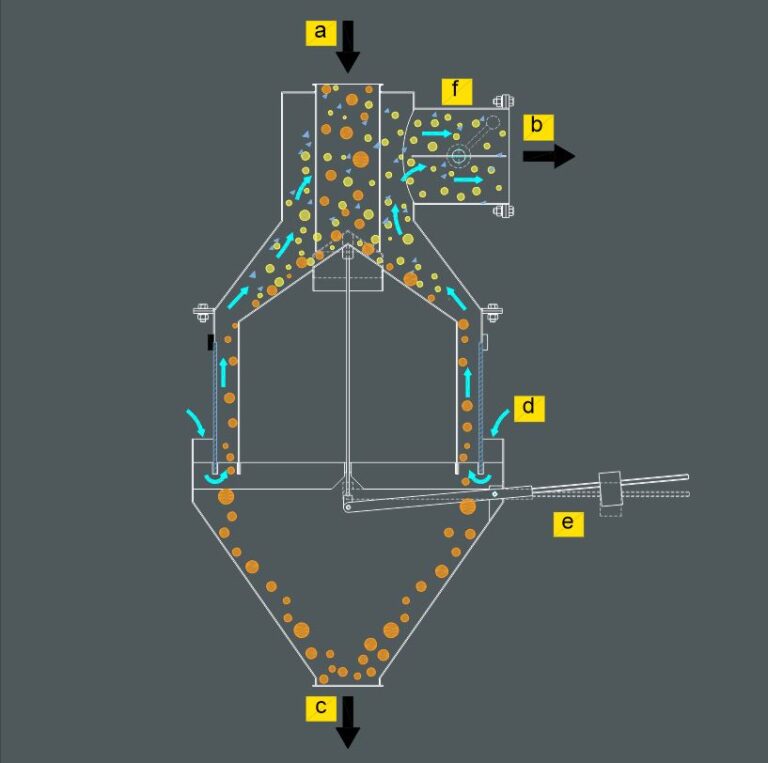

a: Product entry

b: Aspiration with light product

c: Heavy product

d: Air inlet

e: Product entry stamp (Optional)

f: Flow regulator

If we look at the drawing, we can see that the product that enters the tarara through “a” is distributed inside a circular channel with an external viewer. Air circulates through this channel, entering through “d”, and is represented by the blue arrows.

The air lifts the light or less uniformly shaped particles, taking them with it to outlet “b”.

The heavy particles go down and slide to the exit “c”.

Observing the viewfinder and at the same time regulating the air flow with the ‘f’ valve, the type of product that we will have in each of the 2 outlets “c” and “b” can be regulated.