Manufacturing of industrial storage silos for raw materials: Metal silos made of steel, aluminum, or stainless steel, and flexible Trevira® fabric silos.

Silos can be defined as large containers used for storing products in bulk or powder form. Their main characteristics are:

- They are primarily vertical

- They have large capacities

- They can be hermetically sealed

- They can be constructed from various materials

- They can be round, square, or rectangular in cross-section

Product storage can be done in bags or industrial hoppers. However, when large quantities of raw materials need to be stored, we recommend using our metal silos, stainless steel silos, or Trevira® fabric silos.

At Prillwitz, we provide customized solutions for product storage and feeding into the production line. We offer different discharge, conveying, and sifting systems for dry bulk products, depending on the product to be processed. We can also supply feeders, mills for granular products, and state-of-the-art scales that ensure strict production control.

Advantages of using silos instead of bags.

- Silos take up less space

- They facilitate cleaning

- They require less personnel

- They enable automation: When combined with automated extraction and feeding systems, the need for personnel is further reduced, and the possibility of human error is minimized.

Types of silos we can supply:

We have the solution for your dry product storage needs. You can choose from the following types of silos, specifically designed for bulk product storage:

- Flanged and bolted metal silos for Indoor or outdoor use

- Flexible Trevira® fabric silos for indoor use

- Welded metal silos in one unit for outdoor use

Once the type and size of the silo needed have been determined, we will be able to establish its price.

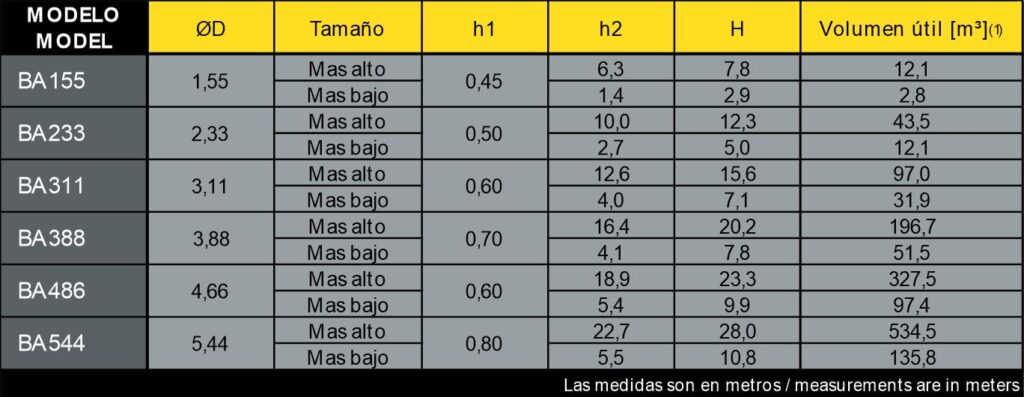

1- Flanged and bolted metal silos BA for indoor or outdoor use

Bolted silos are elevated and specially designed for indoor use, and also for outdoor use when 100% airtightness is not required. They are characterized by their versatility in terms of capacity and geometry (square and circular).

The BA silos are constructed in segments with flanges, making them very easy to transport. They are also convenient for assembly in indoor spaces as they can be brought in disassembled through not-so-large openings.

They may have small constructive differences depending on the need and application, such as:

- Different angles in the discharge cone

- Access ladder

- Access doors

Typically used for indoor applications, but can be made for outdoor use if condensation does not pose a problem for the stored product.

Construction can be in carbon steel or stainless steel according to need.

Typical applications:

- Indoor silos for flours or powders in various industries.

- Outdoor silos for less moisture-sensitive products like grains (wheat for resting or mixing silos), balanced feed, etc.

Technical information

The values di, h1, h2, and H can be modified at the customer’s request and also depend on whether a silo extractor needs to be added.

(1) The usable volume partially depends on the product, as the angles a and b are determined by it

Optionals:

1 – Fixed point or continuous level sensors

2 – Safety valves

3 – Air filters

4 – Air dehumidifiers

5 – Vibratory or fluidizing extractors

6 – Fluidizers

7 – Sight glasses

8 – Load cells to measure weight

9 – Conduits for electrical cabling

More information in the following links

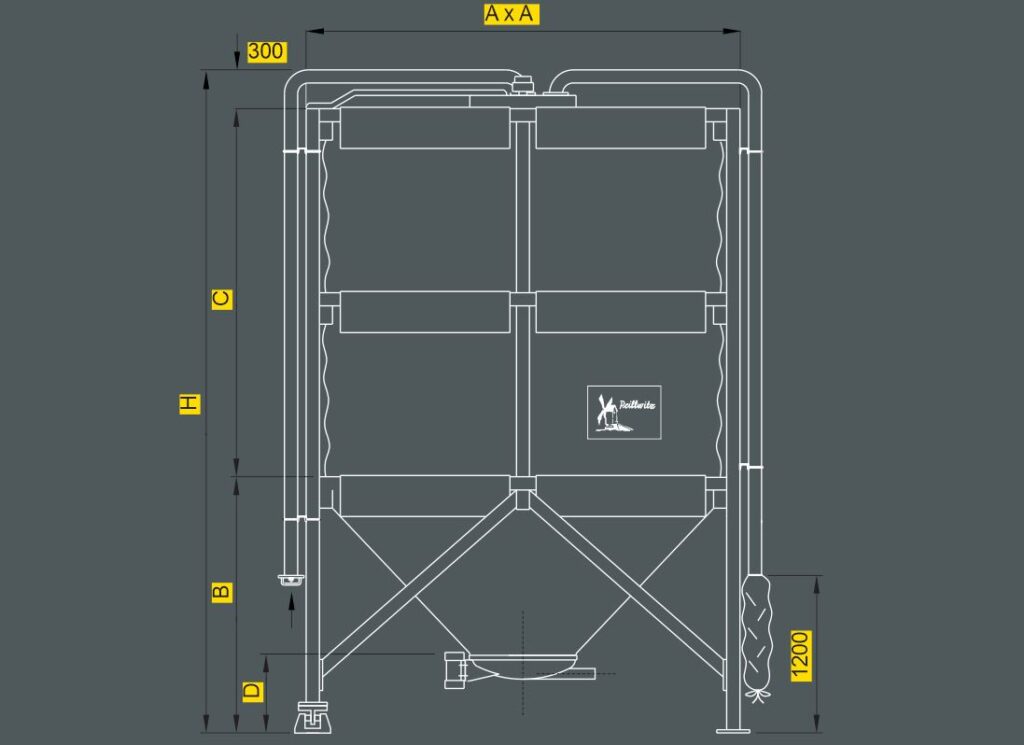

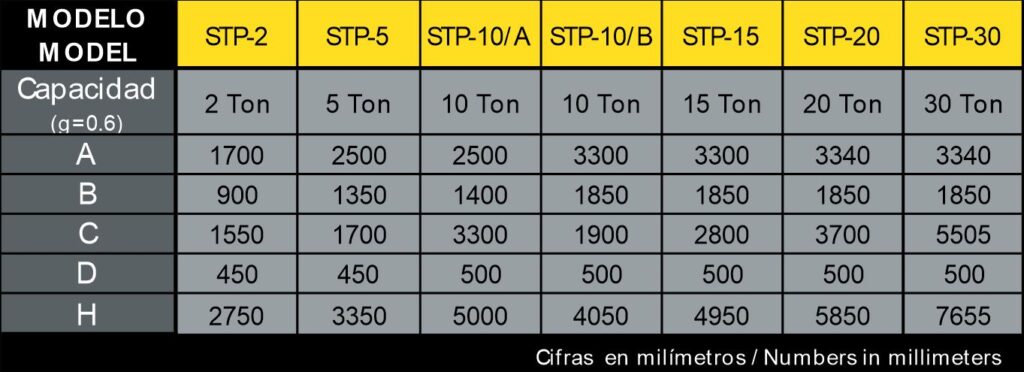

2-Flexible Trevira® fabric silos for indoor use

Flexible Trevira® fabric silos are specially designed to simplify the storage and unloading operations of bulk dry products. Our fabric silos are easily disassemblable and square in section, allowing their use in confined spaces where circular silos would be impossible to install.

This type of silo is suitable for storing raw materials and is used in industries such as chemical, plastic, milling, balanced feed, etc.Trevira fabric has high resistance and some permeability, maintaining product quality through gaseous exchange between the inside of the silo and the outside environment.Storage capacity: 2 to 30 tons.

Typical applications:

- Small indoor silos for flours or powders in various industries.

- Widely used for wheat flour silos in pasta factories and bakeries.

- In the expanded polystyrene industry or Styrofoam for EPS itself, expandable polystyrene, and other raw materials.

Technical information

More information in the following links

3-Welded metal silos in one unit for outdoor use:

Elevated silos specially designed for outdoor use with products that require 100% airtightness.

The product container body in BS silos is constructed as a fully welded unit, ensuring 100% airtightness. This guarantees that no moisture enters or exits.

They may have small constructive differences depending on the need and application, such as:

- Different angles in the discharge cone

- Access ladder

- Access doors

Upper and lower closed environment (BSP Silos)Can be constructed in steel, stainless steel, or aluminum.

Typical applications:

- Outdoor silos for plastic materials: PET, HDPE, PVC, LDPE, PP, PS, etc.

- Outdoor silos for cementitious products like cement, limestone, clay, gypsum, lime, or calcium carbonate, etc.

- For storing wheat flour, corn, or rice in flour mills, pasta factories, and bakeries

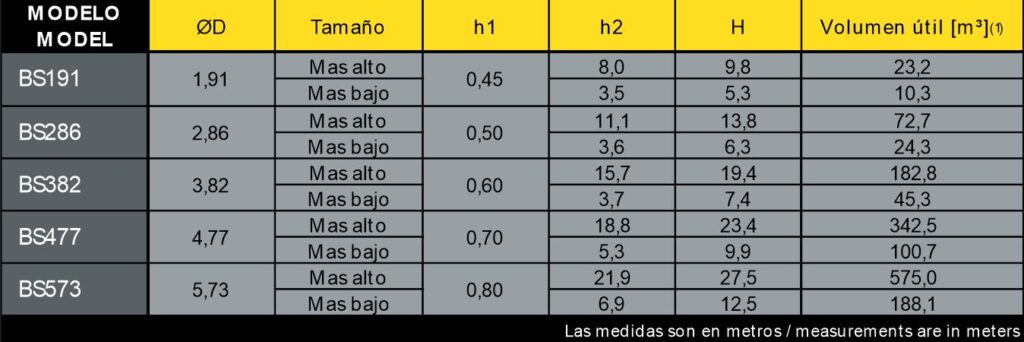

Technical information

The values di, h1, h2 and H can be modified at the customer’s request and also depend on whether a silo extractor needs to be added.

(1) The useful volume depends on the product as the angles a and b depend on it.

Optionals:

1 – Fixed point or continuous level sensors

2 – Safety valves

3 – Air filters

4 – Air dehumidifiers

5 – Vibratory or fluidizing extractors

6 – Fluidizers

7 – Sight glasses

8 – Load cells to measure weight

9 – Conduits for electrical cabling

More information in the following links

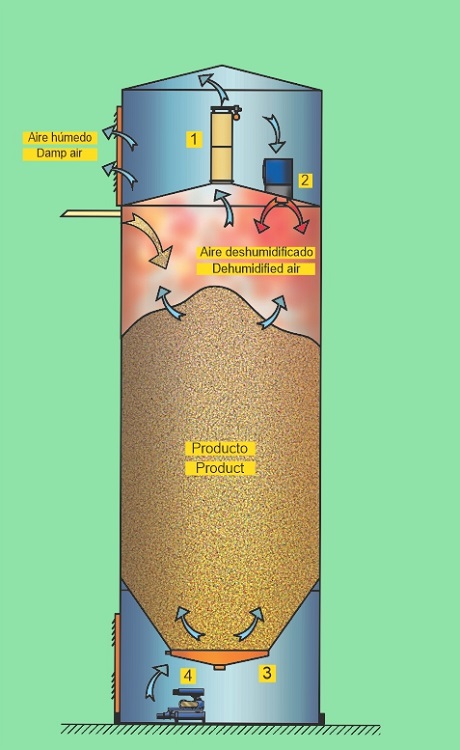

How do we prevent moisture condensation in silos?

Moisture inside silos can cause fundamentally two types of problems:

Moisture in the internal atmosphere condenses and forms water. This happens when the dew point is reached at some time of the day or year and the product cannot absorb it.

Moisture in the internal atmosphere is absorbed by the product, deteriorating it or forming lumps and clumps that prevent silo discharge or subsequent use. This occurs with hygroscopic products, such as sugar, certain plastics, chlorides like table salt, etc.

To prevent moisture, we use “Dehumidifiers.” These machines remove moisture from the air, preventing the dew point from being reached and thus avoiding water condensation.

- Bag filter

- Regenerative dehumidifier

- Vibratory extractor

- Trilobular rotary blower

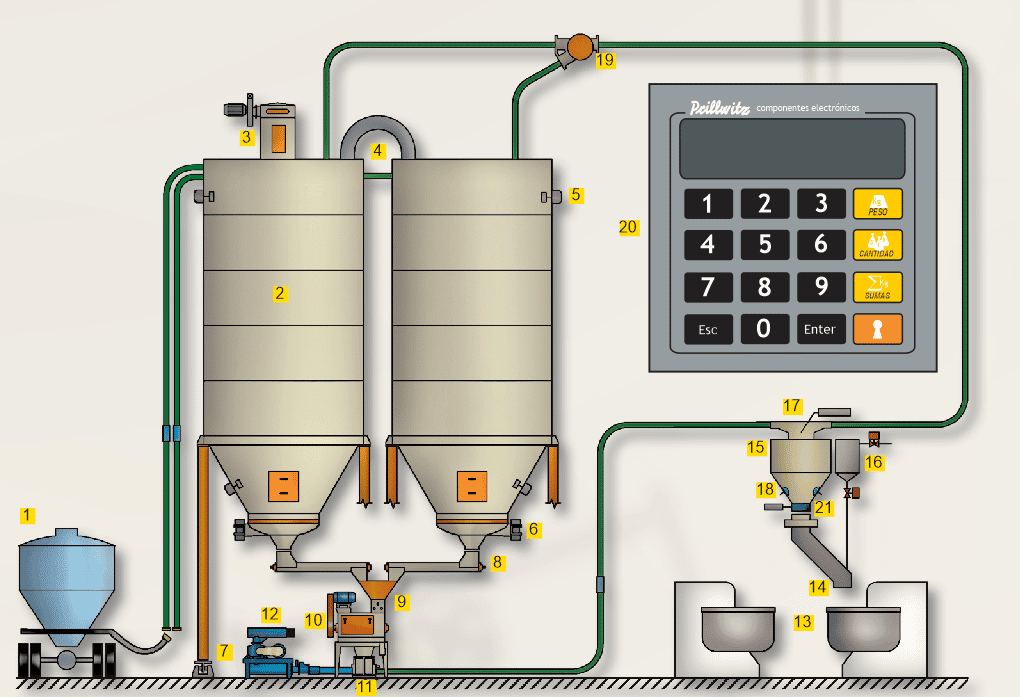

Typical diagram of a bulk storage silo installation with pneumatic transport to production stations:

For the installation of bulk storage systems, we have the necessary machinery to complete the silo installation. Feeding and discharging systems, pneumatic and mechanical conveyors, vibrators and silo fluidizers, dust collectors, cyclones, level indicators and detectors, sieves, mills, rotary valves, etc., are required.

01 Bulk Truck

02 Silos

03 HDF Air Filter

04 Suction

05 Level sensor

06 HAM extractor

07 Scale

08 HSF conveyor screw

09 Magnetic separator

10 Conical screener

11 HSP Rotary Valve

12 ASR Compressor

13 Mixers

14 Rotary Tube

15 Weighing Hopper

16 Water tank

17 Diverter valve

18 Fluidizers

19 Diverter valve

20 Display

01 Bulk Truck

02 Silos

03 HDF Air Filter

04 Suction

05 Level sensor

06 HAM extractor

07 Scale

08 HSF conveyor screw

09 Magnetic separator

10 Conical screener

11 HSP Rotary Valve

12 ASR Compressor

13 Mixers

14 Rotary Tube

15 Weighing Hopper

16 Water tank

17 Diverter valve

18 Fluidizers

19 Diverter valve

20 Display

Some products that can be stored in silos:

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Rice

- Girassol

- Chickpeas

- Soybeans

- Peanuts

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Fish flour

- Milk powder

- Dried beans

- Bread crumbs

- Batter

- Aluminum powder

- Atrazine

- Bentonite

- Borax powder

- Lime

- Caolin

- Activated carbon

- Calcium carbonate

- Cement

- Shell

- Quartz

- Titanium Dioxide

- Dolomite

- Fertilizers

- Monoammonium Phosphate

- Diammonium Phosphate

- Tricalcium Phosphate

- Mica

- Refractory Materials

- Sodium naphthalenesulfonate

- Pigments

- Soaps

- Salt

- Precipitated silica

- Caustic soda

- Magnesium sulfate

- Zinc sulfate

- Tanine

- Diatomaceous Earth

- Dyes

- Gypsum

- Lithium

- Afrecho and afrechillo

- Wheat semolina and semolina

- Semolina

- Rebasillo

- Zootechnical flour

- Maize semolina

- Semolina

- Polenta

- Wheat flour, corn flour, soy flour, etc.

- Germ

- Starch

- Hull

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap poder

- Pigments