Prillwitz also provides machinery for bakeries, cookie factories, confectioneries, pasta factories, and other flour consumers. For them, we have the most complete systems for storage and handling of bulk dry products, equipment for unloading maxi-sacks and big bags, as well as high-speed ingredient mixers.

The installations of flour, semolina, and husk silos store products directly received from bulk trucks or big bags.

Advantages of handling these products in silos instead of bagged:

– Staff savings

– Space savings

– Greater cleanliness

– Avoids human error

– Cheaper flour. Only in some countries.

Saves the weight of the bag and the residue left in it when emptied. Studies have shown that this value is approximately 2.5%.

– Better flour quality: Mainly because returns are difficult with this type of installation, the mill takes special care with its quality.

Wheat flour silos in a pasta plant

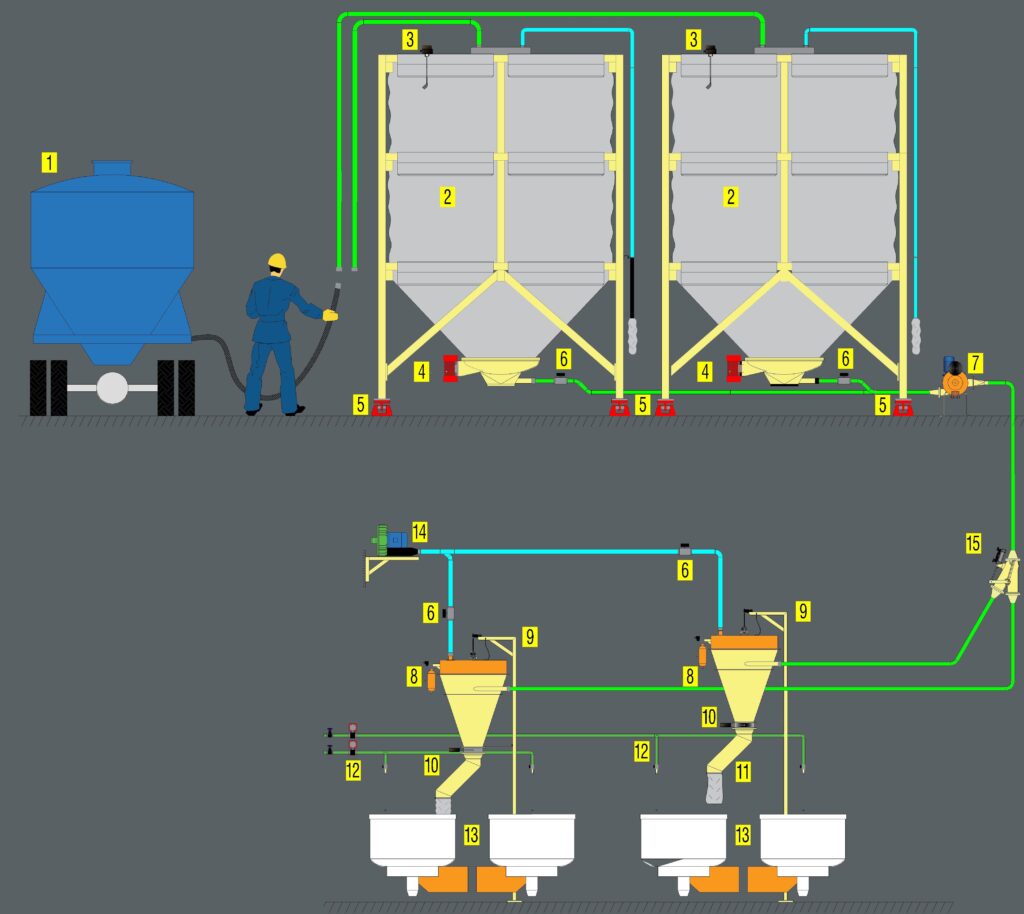

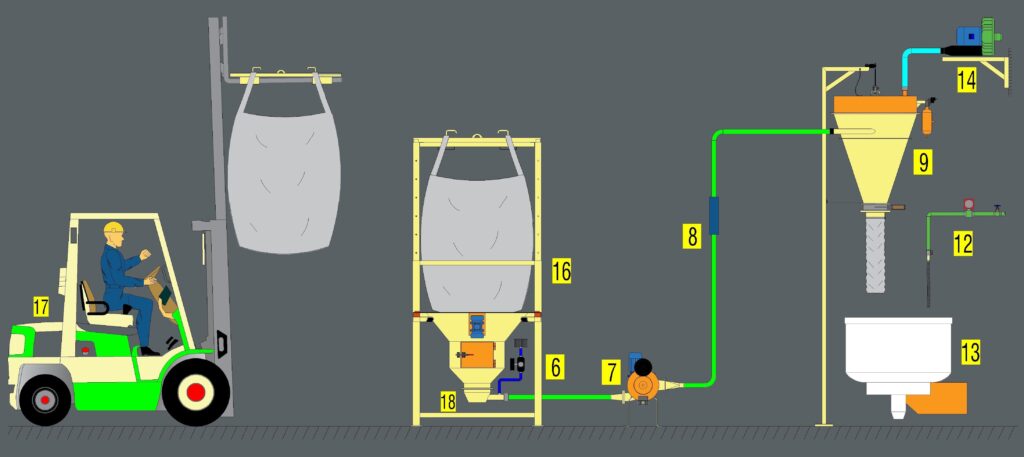

Example diagrams of installations with reception, storage, and mixing of flour and water for bakeries.

01- Bulk truck

03- Level sensor

04- HAM extractor

05- Scale

06- Electropneumatic valve

07- In-line sifter

09- Weighing hopper

10- Discharge valve

11- Rotating tube

12- Water dosing

13- Mixers

15- Diverter valve

16- Big bag unloader

17- Forklift

18- Dam box

What do we need to know to size a flour silo installation for you?

If you need us to make a proposal suitable for your needs, we would need you to send us the following information:

- Daily consumption of each product. Flour in its different types, sugar, starch, etc.

- Height of the place for silos: minimum of 3.5 meters, otherwise consider placing special outdoor silos.

- Distances from the truck to silos and from silos to discharge or consumption points.

- How will you receive the flour: By bulk truck or with Big-Bag.

- Number and type of discharge points, with individual consumption. The different types of discharge are:

– With scale. The capacity of the mixer is weighed. Flours can be mixed. Water dosing is optional.

– Discharging directly into the deposit with level controls that send the start and stop signal and a valve for discharge.

– With cyclone and rotary airlock valve for continuous discharge.

Products we can process in bakeries and pasta factories

Productos que podemos procesar en panificadoras y fábricas de pastas

- Harina de Trigo

- Harina de maíz

- Harina de arroz

- Afrecho y afrechillo

- Semita y semitín de trigo

- Semolina

- Rebasillo

- Harina zootécnica

- Semola de Maiz

- Semola

- Polenta

- Germen

- Almidón

- Azúcar cristal

- Azucar impalpable

- Cacao

- Coriandro

- Curcuma

- Gelatina

- Leche en polvo

- Legumbres secas

- Pan rallado

- Rebozador

- Bórax en polvo

- Carbonato de Calcio

- Dióxido de Titanio

- Dolomita

- Fosfato Monoamonico

- Fosfato Diamonico

- Fosfato Tricalcico

- Sal

- Sulfato de Magnesio